RASACUT OC

Perforated tubes are often used in automobile construction, especially in the constructon of silencers. And in the manufacture of rack systems, tubes with exact spacing between holes are absolutely necessary.

In the manufacture of perforated tubes, there are of course deviations in the intervals in punched ranges. High process costs in manual fixed length re-cutting are the result.

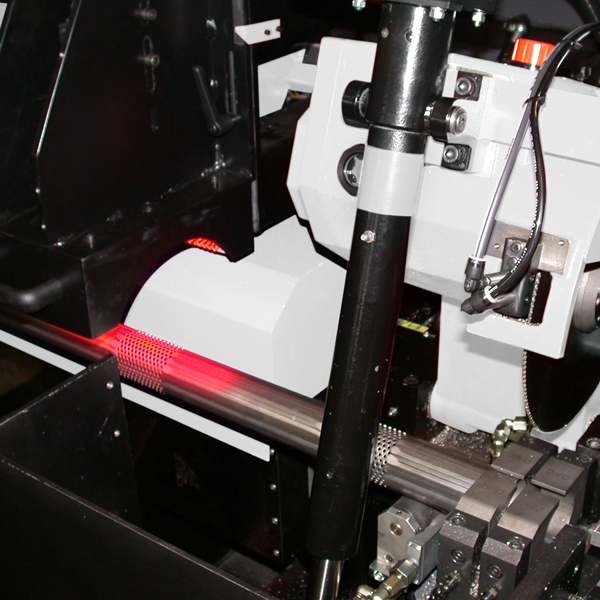

The RASACUT OC cuts perforated tubes fully automatically and ejects defective perforation intervals in the output material by itself. It reduces the high expenditures for work and material for cutting output lengths of pre-perforated tubes drastically.

tubes from a bundle of tubes are automatically separated and transported to the saw with a gripper. This highly precise feed is controlled by an optical systems that automatically measures the distances between punches and makes sure that the cuts between the punch point and the end of the tube are always within the prescribed tolerance.

Sections in the output material in which the punching intervals are impermissibly large relative to each other are cut out and ejected. The result is drastically reduced process costs through increased output on the one hand and discontinuation of 100% controls after the fact as well as less reject material.

Automatic recognition and positioning of the weld seam is possible as an option.

Advantages

More Output, Less Rejection

Your time advantages:

- High output

- Analogous to perforation measurement, positioning of the output length using gripper feed (no reduction in transport speed)

- Fully automatic measurement of perforation intervals

Your quality advantages:

- Perforations outside of the tolerance will be automatically separated from the fixed length

- Highly precise cutting

- Touchless measurement of perforations in the output lenghts

- Fully automatic control of bar feed analogous to the measurement data

Your cost advantages:

- The optical measurement system checks the perforation intervals in tubes and thus increases output

- 100% control after the fact is not necessary

- Less reject

MOBILE DEMONSTRATION SERVICE

Nothing’s more convincing than first-hand experience. We will gladly allow you to test whether our deburring systems are suitable for your parts – free of charge and non-binding. Not only here on site in Lüdenscheid but also at your factory site.

That’s precisely why we developed our mobile demonstration service, which will come to you. On board you will find brushes and deburring machines, which you can then test on your parts.

Schedule your appointment now by calling 01952 585183 or filling out the form below

Specifications

Technical Specifications

[Cutting Speed: continuous] 30 to 250 m/min.

Saw Blade Diameter: 315 mm

Saw Motor: 7.5 kW

Work Piece Positioning: Gripper feed

Bar section: > 20 mm

Remnant: > 80 mm

Workpiece data

Work materials: Steel, stainless steel, non-ferrous metals

Round tube: Ø 10 to 90 mm

Wall thickness: 1 to 3 mm

Fixed lengths: 30 to 2,000/3,000 mm