RASACUT XS

RASACUT XS is the alternative to multiple or bundle cut saws in the manufacture of large-scale series with diameters of 6 to 50 mm. With the single-cut saw RASACUT XS, you improve your quality, reduce unit costs and guarantee high part quality.

Areas of application include fuel and brake lines or visible elements such as head rest supports.

An essential advantage lies fully automatic process sequence. Through the consistent reduction of auxiliary process times, the RASACUT XS achieves output levels in single cut operation that are just as high as multiple or bundle-cut saws, depending on the measurement range, even higher!

Do you need a multiple cut saw for small diameters? Then learn about the RASACUT MXS!

Here’s how the RASACUT XS Reduces your Time and Costs

In-feed

In bundle-cut saws, the tubes are bundled together manually. The work pieces are manually counted and bundled and fed into the saw. With the RASACUT XS, the tubes are automatically separated and fed via two independent grippers. This reduces the auxiliary process times for bar switching to a minimum.

Additional tube processing after the cut.

After separation, the fixed lengths come apart uncontrolled. Additional logistical effort is required to feed the cut tubes to the next stage in processing, such as de-burring– either an automated separator or manually filling a magazine. The RASACUT XS, by comparison, can be modularly expanded into a reliable processing centre.

Advantages

High Total Output with High Precision

Your time advantages:

- Through the use of two feeding grippers, auxiliary process times for bar switching are reduced to zero.

- Minimal set-up times

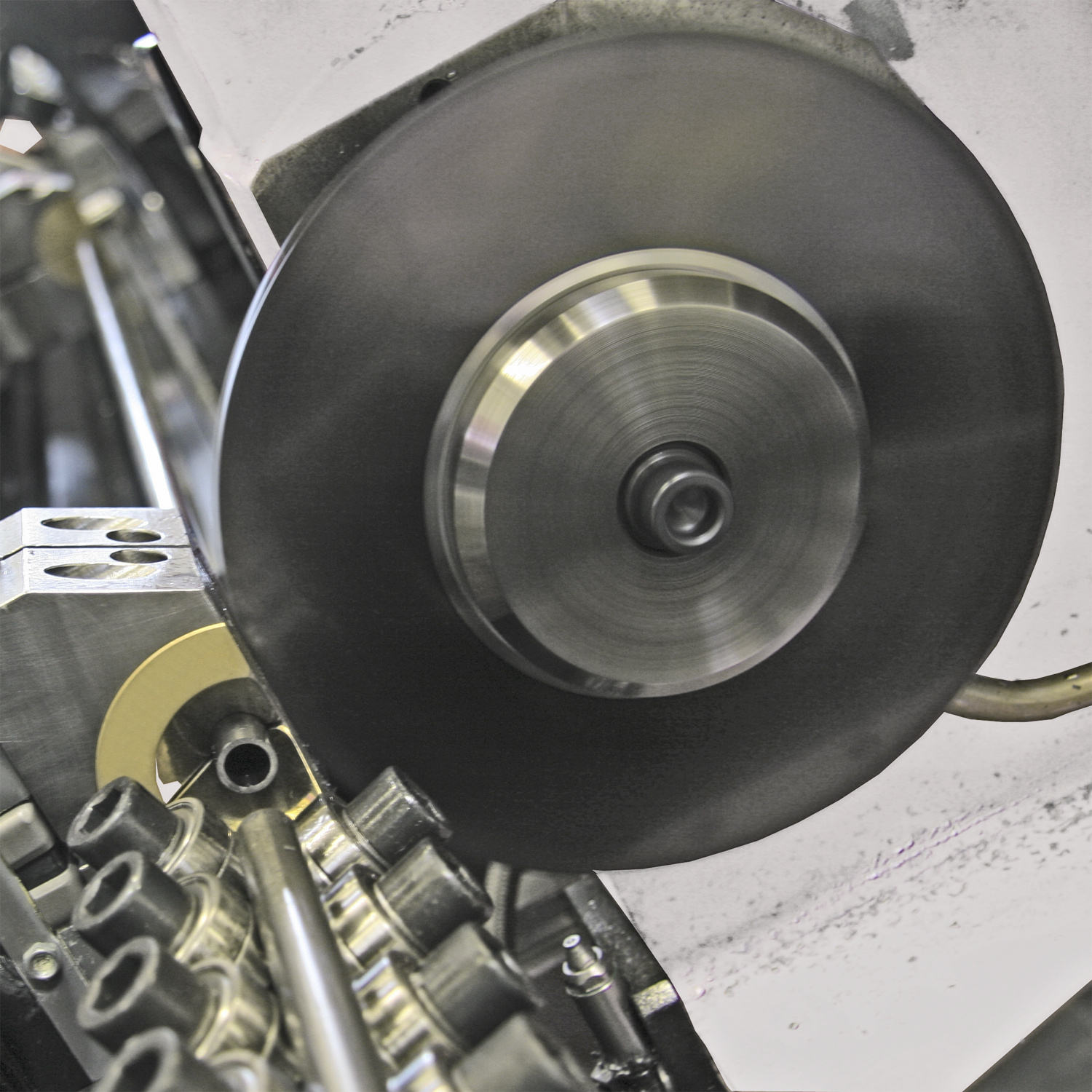

- Saw blade replacement in under 1 minute

- Central tensioning on work pieces makes it possible to use saw blades with small diameters and high RPMs, which increases precision and drastically reduces tool costs.

Your quality advantages:

- High precision and cut quality thanks to high precision positioning

- Excellent protection of the surface thanks to coated tools

- Saw bow feed and work piece travel using servo motors

- HSS, solid carbide or carbide-dipped saw blades available

Your cost advantages:

- Drastic reduction of cut costs through high output and saw blade durability as well as low saw blade costs

- Unlike bundle saws, separting the tubes from the crane load and feeding to the saws is fully automatic in the RASCUT XS

MOBILE DEMONSTRATION SERVICE

Nothing’s more convincing than first-hand experience. We will gladly allow you to test whether our deburring systems are suitable for your parts – free of charge and non-binding. Not only here on site in Lüdenscheid but also at your factory site.

That’s precisely why we developed our mobile demonstration service, which will come to you. On board you will find brushes and deburring machines, which you can then test on your parts.

Schedule your appointment now by calling 01952 585183 or filling out the form below

Specifications

Technical Specifications

[Cutting Speed: continuous] 30 to 450 m/min.

[Saw Blade Diameter:] 175/200 mm

Saw Motor: starting at 4.7 kW

Work Piece Positioning: Gripper feed

Bar section: > 15 mm

Remnant: > 50 mm

Workpiece data

Work materials: Steel, stainless steel, non-ferrous metals

Round tube: Ø 6 to 50 mm

Wall thickness: 1 to 3 mm

Input lengths 6,000 mm

Fixed lengths: 20 to 1,000/1,500//2,500 mm

Other dimensions on request