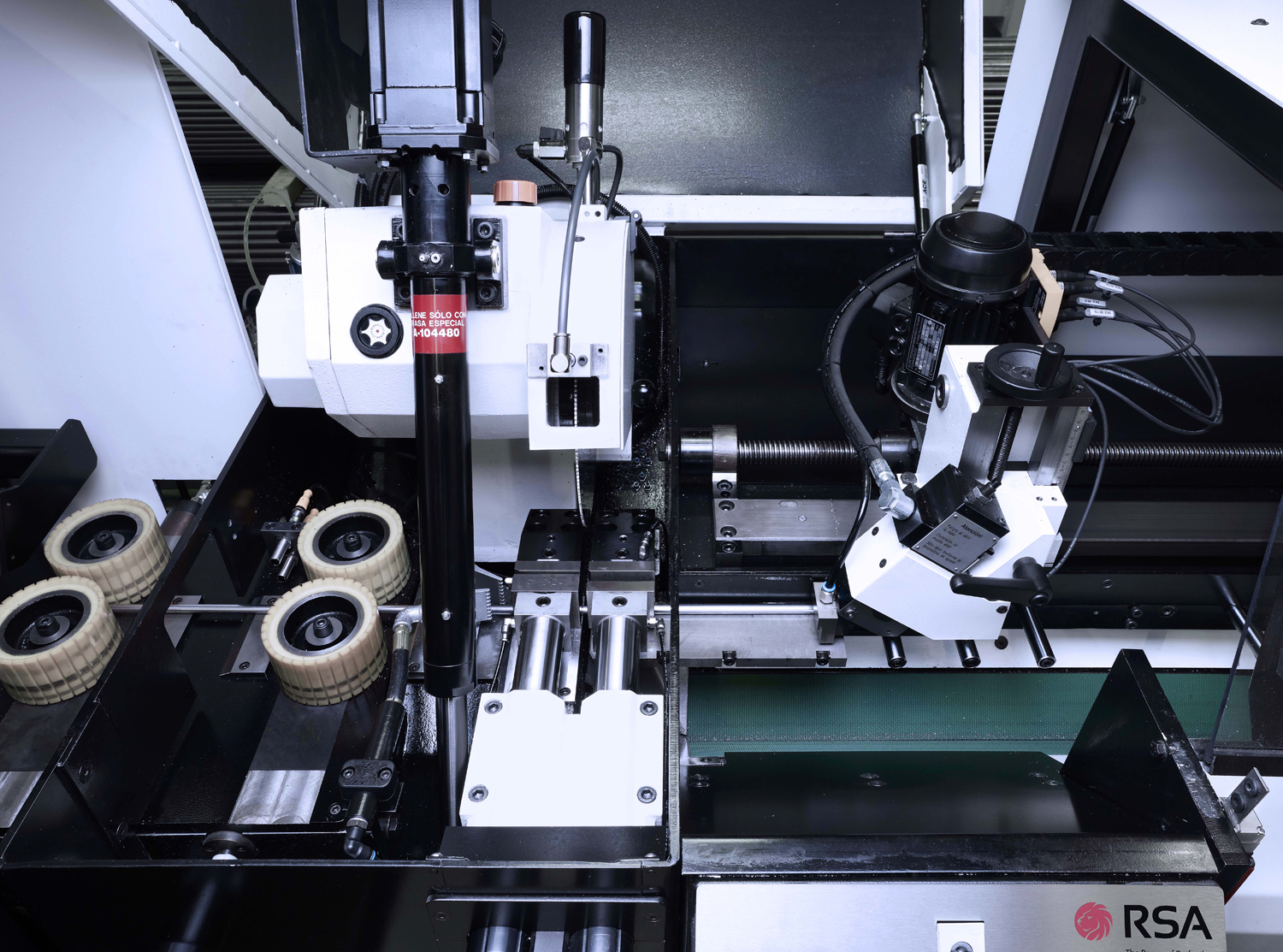

RASACUT SC

RASACUT SC is a universal, highly precise high performance saw for a variety of applications, for example in the automotive, steel trade, furniture and scaffolding industries.

RASACUT SC is a single-cut saw with a wide range of diameters that guarantees high output with minimal set-up times.

Thanks to its unbelievably robust construction, it can be used in a steel works as well as in CNC-sawing and is suitable for three-shift operation.

Operator instructions are provided primarily through pictogrammes and available in nearly all national languages. Control thus demands no CNC-skills from the operator to set the parameters.

Advantages

Fast, Precise, Economical through Perfect Details

Your time advantages:

- Length changes in less than 1 minute

- Easily accessible saw blade. Changeover in less than 1 min

- Completely automated positioning of the stops and the saw blade

- Database referenced to work pieces for optimal deburring performance, no programming

- Quick format change in under 5 minutes

Your quality advantages:

- Better cut quality through variable advance on starting and ending the tube cut

- Aircooler provides even cooling using compressed air: Higher blade lifetime, better cut quality, clean work pieces

- Length stop mechanically self-stopping and with additional electrical clamping, high repeat precision

- Exact, fast tension that is gentle on the surface thanks to power and travel presettings

- Saw drives that are are extremely durable, long-lived and precise, nearly free of play

Your cost advantages:

- High output, resulting in low cost per piece

- Use of carbide saw blades also possible

- Suitable for three shift operation, soft and hard material grades

- Minimal quantity lubrication provides for optimal lubrication, low operating and disposal costs

- Options

MOBILE DEMONSTRATION SERVICE

Nothing’s more convincing than first-hand experience. We will gladly allow you to test whether our deburring systems are suitable for your parts – free of charge and non-binding. Not only here on site in Lüdenscheid but also at your factory site.

That’s precisely why we developed our mobile demonstration service, which will come to you. On board you will find brushes and deburring machines, which you can then test on your parts.

Schedule your appointment now by calling 01952 585183 or filling out the form below

Specifications

Technical Specifications

Cutting Speed: continuous 30 to 250 m/min.

Saw Blade Diameter: 315/350 mm

Saw Motor: 7.5 kW

Work Piece Positioning: 1 length stop, movable using electric motor (2 stops optional)

Bar Section: 0 or > 20 mm

Remnant: > 35 mm

Workpiece data

Work Materials: Steel, stainless steel, non-ferrous metals

Round tube: Ø 10 to 101.6 mm

Square tube: 10 x 10 to 75 x 75 mm

Rectangular tube: 10 x 15 to 70 x 80 mm

Wall thickness: 1 to 10 mm (max. 10 kg/m)

Solid material: Ø 10 to 40 mm

Input lengths 6,000 to 12,000 mm

Fixed lengths: 30 to 1,000/2,000/3,000/4,500 mm

Other dimensions on request